The necessity of regular maintenance of double-shaft shredder equipment

Date: 2024-09-12 Categories: Industry News Hits: 661

The necessity of regular maintenance of double-shaft Shredder equipment.

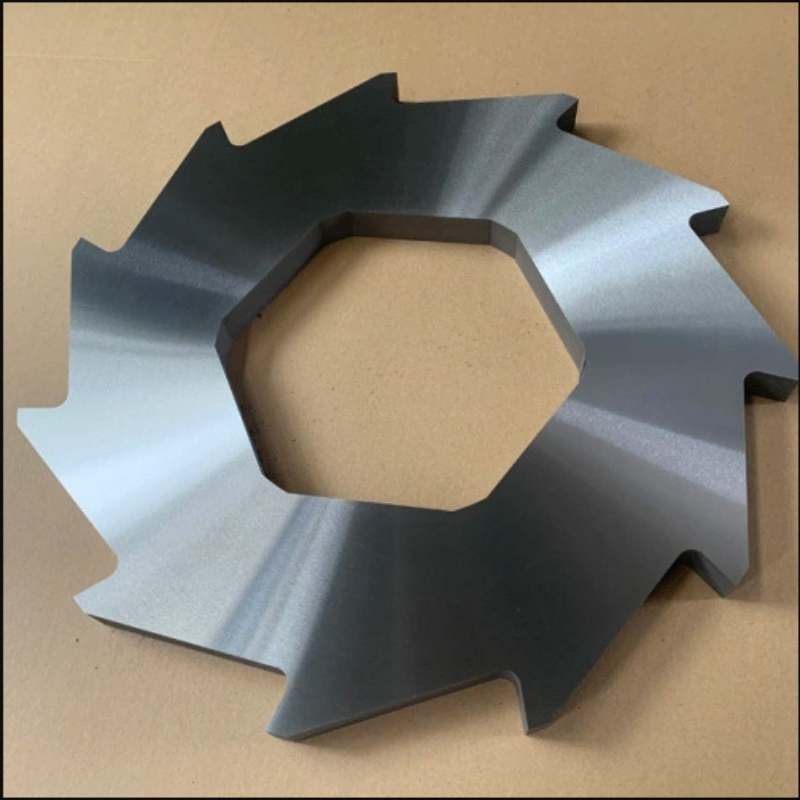

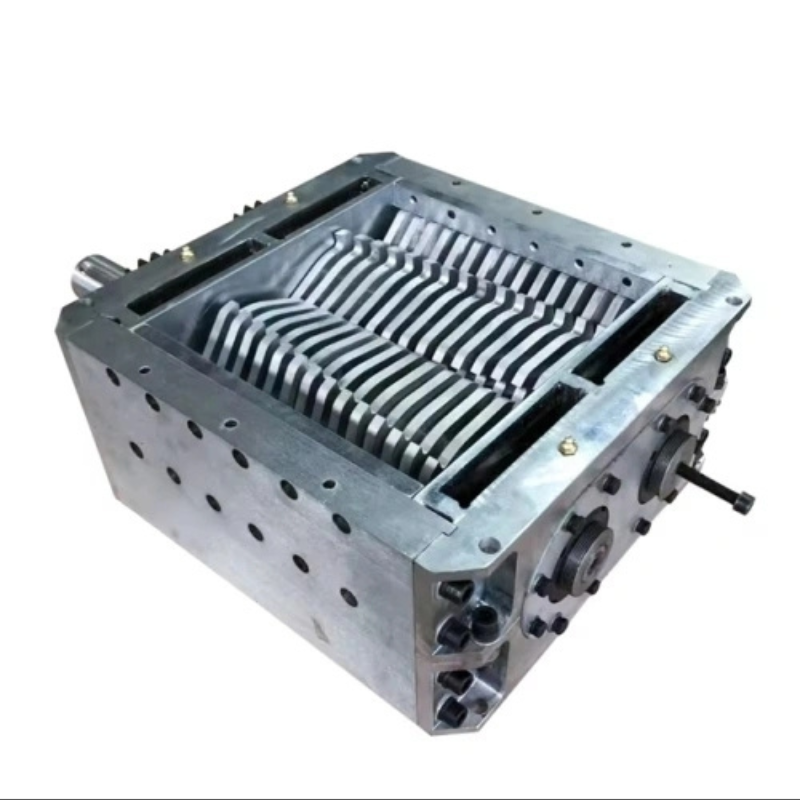

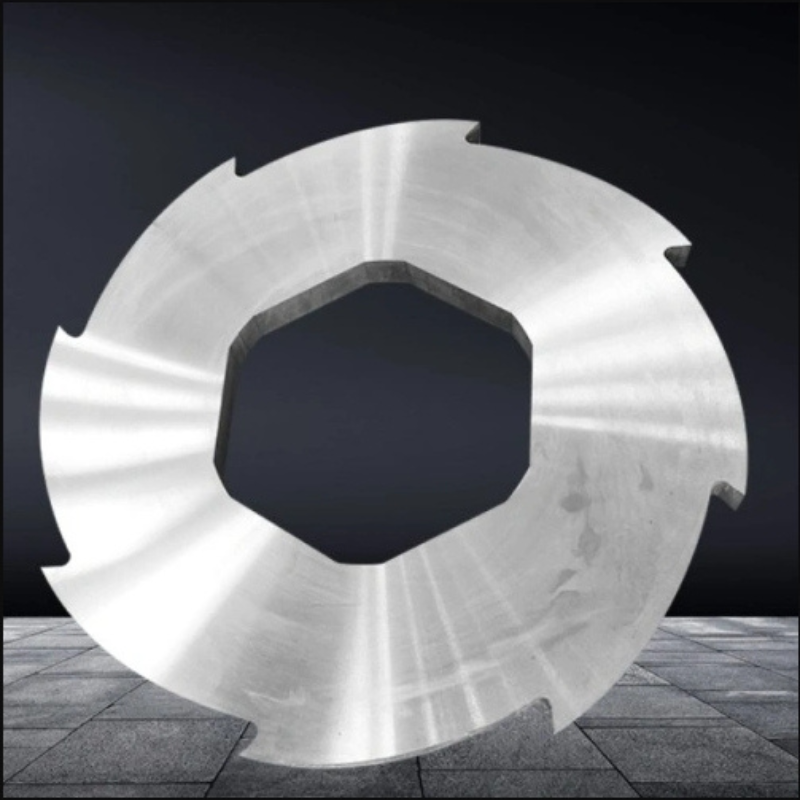

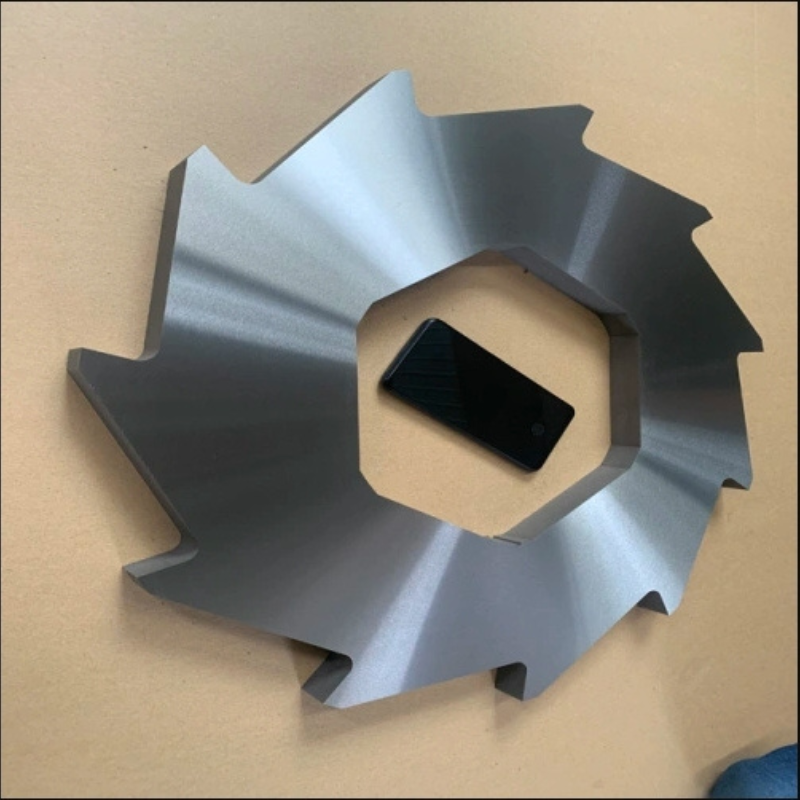

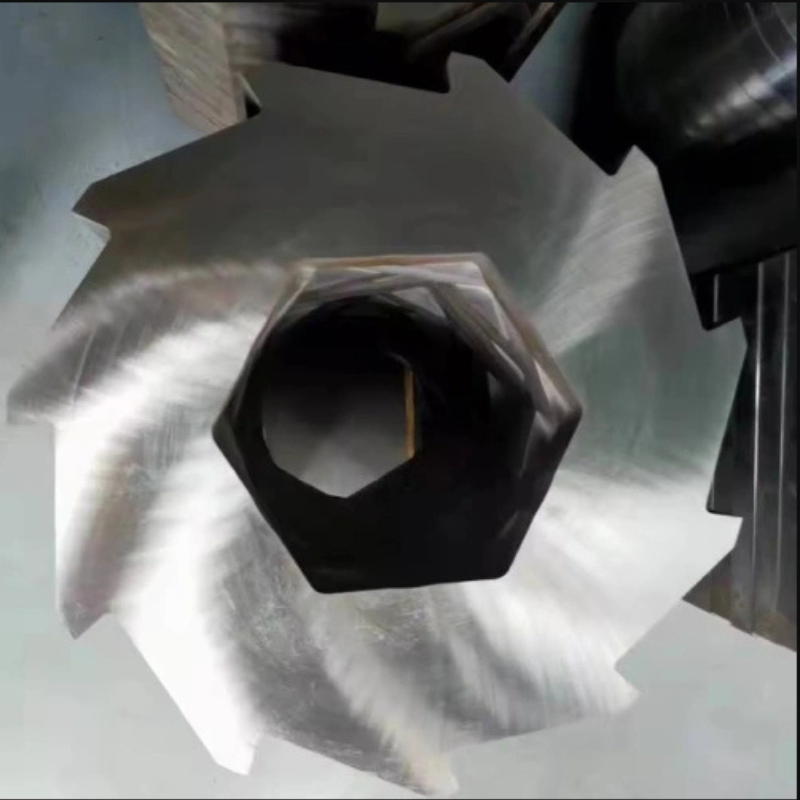

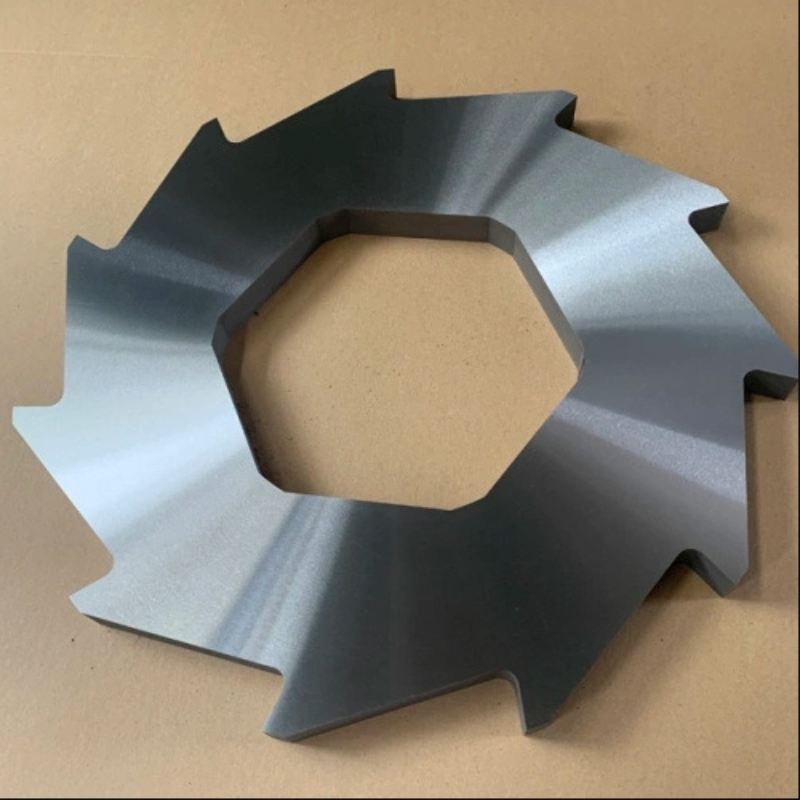

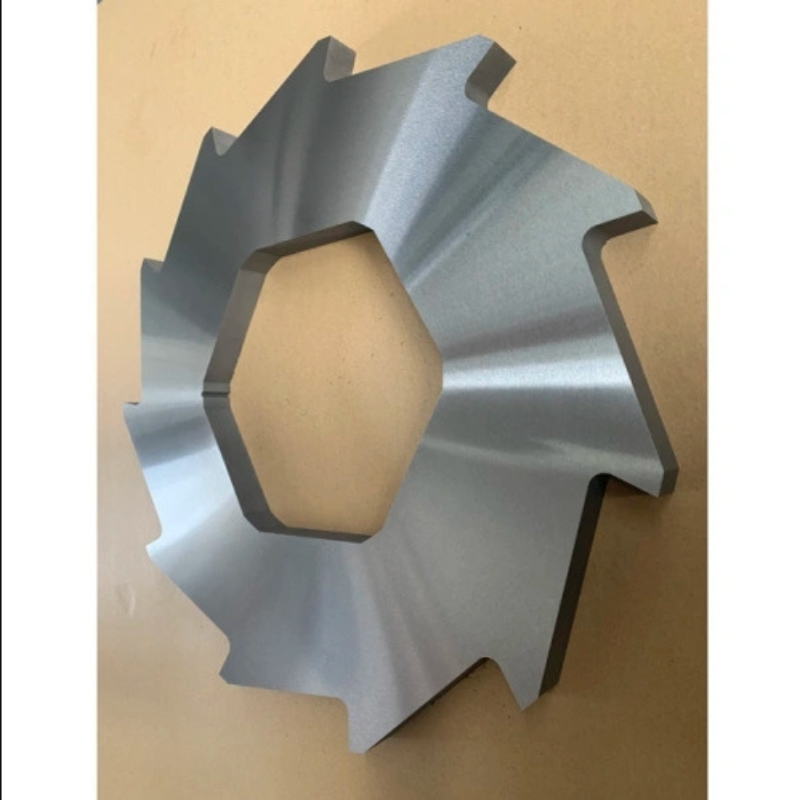

The double-shaft shredder is a device that reduces the size of materials by shearing, tearing and squeezing. The metal shredder has a wide range of processing and is well received by customers. In order to achieve a better Shredding effect, it is necessary to regularly maintain and service the double-shaft shredder.

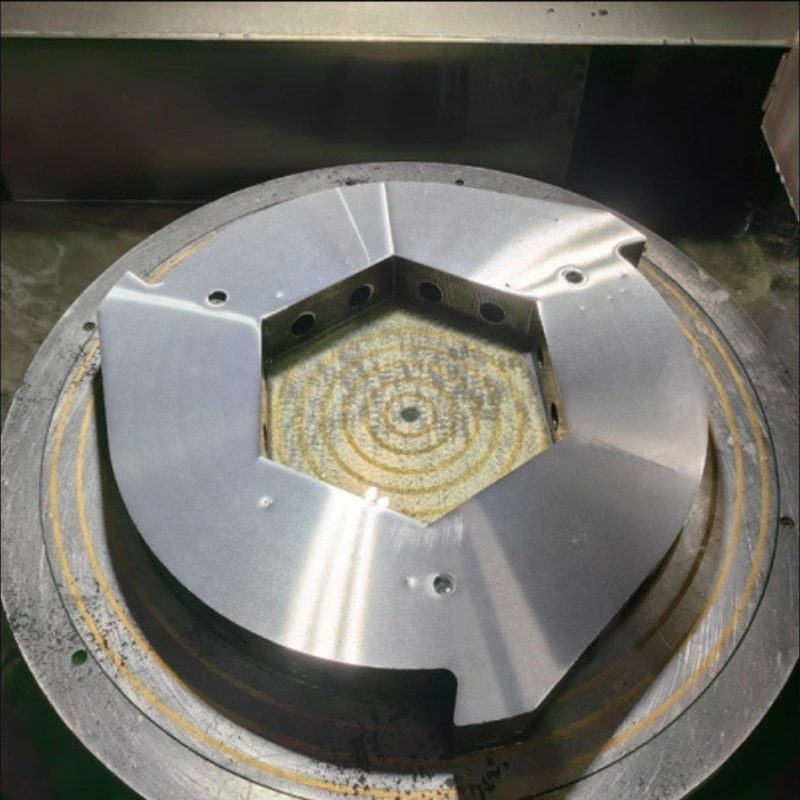

1. Maintenance principles of double-shaft shredder equipmentThe maintenance of double-shaft shredder equipment should be divided into daily, weekly, monthly, quarterly and annual inspections. Perform a small inspection every day to check the machine sound, foreign objects in the machine cavity, screw parts, etc., check the electrical parts every week, and check and lubricate the shredder tool parts every month. Only by opening the correct maintenance method can the double-shaft shredder equipment be better used by us, thereby increasing the service life of the shredder.

2. Replacement of lubricating oil of double-shaft shredder reducerThe reducer is a transmission device that uses the speed converter of the gear to produce low speed and high torque. It is a key equipment to ensure the production power of the double-shaft shredder. The reducer is equipped with lubricating oil. The lubricating oil should be replaced regularly. The reducer of the double-shaft shredder must be replaced after the first operation reaches 400 hours. Each time the lubricating oil is replaced, the lubricating oil in the original reducer must be completely drained before other operations.

3. Maintenance instructions for bearings of double-shaft shredderIn order to keep the double-shaft shredder in good working condition and reduce the occurrence rate of failures, bearing maintenance is also indispensable. The temperature of the main bearing is too high. It may be that the grease is insufficient, so an appropriate amount of grease needs to be added; the grease is contaminated, so the grease needs to be cleaned and replaced. Before replacing the lubricating oil, use petroleum ether or other bearing cleaners to clean the bearing dirt. After cleaning, lubricant should be applied immediately to prevent corrosion. Bearings do not need to be replaced under normal circumstances. If the main bearing needs to be disassembled and replaced, it must be completed by professionals. Users and customers should contact the manufacturer for specific matters.

4. Other common maintenance issues of double-shaft ShreddersThe double-shaft shredders have problems such as reduced processing capacity or insufficient power, uneven feeding, and foreign matter entering the feed port. In order to keep the double-shaft shredder in good working condition, reduce the occurrence of failures, improve work efficiency, and extend its service life, we need to do a good job of daily maintenance and maintenance of the shredder.

|

|

HSS Double Shaft Metal Tyre Re...

HSS Double Shaft Metal Tyre Re...  Recycling Shredder Blades For ...

Recycling Shredder Blades For ...  Twin Shaft Shredder Blade for ...

Twin Shaft Shredder Blade for ...  High Quality Shredder Blade Fo...

High Quality Shredder Blade Fo...  Customized Double Shaft Metal ...

Customized Double Shaft Metal ...  High Quality Multi-axis shredd...

High Quality Multi-axis shredd...  Double Shaft Shredding Machine...

Double Shaft Shredding Machine...  High Quality Double Shaft Shr...

High Quality Double Shaft Shr...  Double Shaft Shredder Blade fo...

Double Shaft Shredder Blade fo...  Customization Shredder Machine...

Customization Shredder Machine...  Waste Plastic Shredder Blades ...

Waste Plastic Shredder Blades ...  Best Quality Double Shaft Plas...

Best Quality Double Shaft Plas...  High Quality Single-axis shred...

High Quality Single-axis shred...  PET Bottle Recycling Shredder ...

PET Bottle Recycling Shredder ...  Double Shaft Shredder Blades F...

Double Shaft Shredder Blades F...  E-waste Recycling Double Shaft...

E-waste Recycling Double Shaft...  E-Waste Recycling Shredder Bla...

E-Waste Recycling Shredder Bla...  Waste Wood Shredder Blade With...

Waste Wood Shredder Blade With...  Double Shaft Shredder Blade fo...

Double Shaft Shredder Blade fo...  Biomass Double Shaft Shredding...

Biomass Double Shaft Shredding...  Recycle Shredder Blade For Do...

Recycle Shredder Blade For Do...  Tire Rubber Waste Granulator S...

Tire Rubber Waste Granulator S...  High Quality Tyre Cutting Shre...

High Quality Tyre Cutting Shre...  Shredder Cutting Blade for Cru...

Shredder Cutting Blade for Cru...